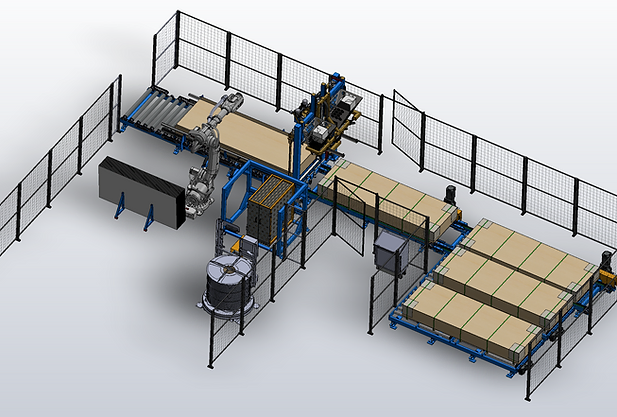

Machine Design

- High-precision engineering

- Robust mechanical framework

- Advanced automation capabilities

- Modular component design

On-site Service Support

- Comprehensive Installation Assistance

- Preventative Maintenance Programs

- Breakdown Rapid Response

- Customized Training Sessions

Spare Parts

- Extensive Inventory of Genuine Parts

- Fast and Reliable Delivery

- Expert Parts Assistance

- Cost-Effective Parts Packages